Exploring the World of PCB Test: A Comprehensive Guide

Are you curious about pcb test and its significance in the electronics industry? Join me on this journey as we delve into the world of PCB board testing, uncovering its importance and exploring its various aspects.

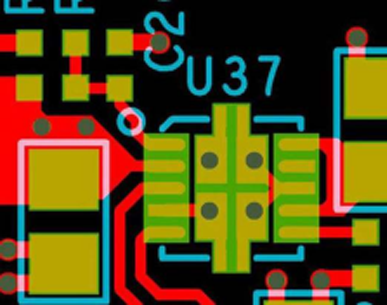

The Significance of PCB Board Testing

pcb board testing plays a crucial role in ensuring the functionality and reliability of electronic devices. By subjecting printed circuit boards to rigorous tests, manufacturers can identify any defects or faults before they reach consumers. This not only helps in maintaining product quality but also saves time and resources by preventing costly recalls or repairs.

Different Methods Used for PCB Testing

There are several methods employed for PCB testing, including automated optical inspection (AOI), in-circuit testing (ICT), functional testing, and burn-in testing. Each method serves a specific purpose, allowing manufacturers to detect different types of issues such as soldering defects, component failures, or overall system performance.

The Role of JinHua in Massachusetts’ PCB Testing Industry

JinHua is a leading provider of advanced test solutions for the electronics industry based in Massachusetts. With their state-of-the-art equipment and expertise, they have revolutionized the way PCBs are tested. Their innovative technologies ensure accurate detection of even the most intricate faults while improving efficiency and reducing production costs.

In Conclusion

From understanding the significance of PCB board testing to exploring different methods used for thorough examination, it becomes evident that this process is indispensable in guaranteeing reliable electronic devices. Thanks to companies like JinHua pushing boundaries with cutting-edge technology, we can expect further advancements in this field that will continue to enhance product quality across industries.